Blog

Hot Category

Latest Blog

24 Jan 2025

Nlelsen

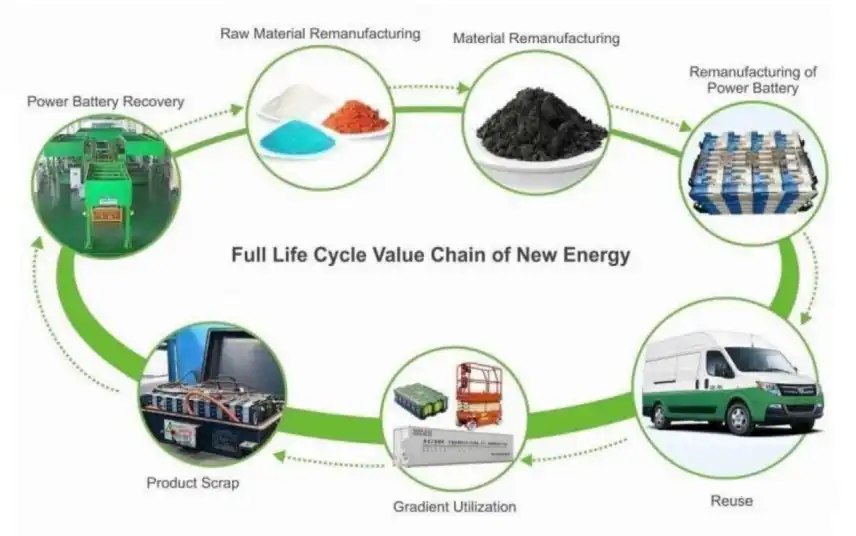

With the widespread application of lithium iron phosphate batteries in new energy vehicles and other fields, its recycling issue has received increasing attention. The following are some common recycling methods:

First, the waste lithium iron phosphate battery needs to be disassembled to remove the positive electrode material part. The disassembled battery often needs some pretreatment before subsequent treatment. For example, it is necessary to dissolve it in a hydrochloric acid solution, then adjust the pH value to near neutral with ammonia water, and remove the precipitate by filtering to obtain a lithium-containing electrolyte. This process is to better separate and extract the metal elements in it later.

● Wet recycling is to extract valuable metals from waste batteries using chemical precipitation, solvent extraction, adsorption and other technologies.

● Its advantage is that it has a high recovery rate and purity. However, the investment cost of this recycling method is relatively high.

● Before recycling, the waste lithium iron phosphate batteries need to be crushed and screened, and the screening accuracy is crucial to the recycling quality. Generally speaking, the waste batteries will first be subjected to steps such as charged crushing, pyrolysis, and screening to obtain waste lithium iron phosphate battery powder.

● Then, a series of steps such as high-temperature treatment of these powdered materials are used to purify the metal elements. This method is relatively low-cost, but it may produce more pollutants during the treatment process, and strict environmental protection measures such as tail gas treatment are required.

● For example, one method is to use FepO4 material to directly enrich the lithium in the solution from the positive electrode material solution through an electrochemical method.

● The specific steps are to place the iron phosphate electrode and the graphite plate electrode in the above-mentioned lithium-containing electrolyte, and perform an electrochemical reaction to obtain lithium.

● Afterwards, the iron phosphate can be regenerated, such as adding LiOH to the iron phosphate at a molar ratio of Li to Fe of 1:1, and then adding sucrose, drying, and vacuum drying the dried product and grinding it evenly, and calcining it in an inert atmosphere to obtain LiFePO4/C products.

● Biorecycling is the use of microorganisms to degrade organic matter in batteries and recover metals. Although this technology is still in the research stage, it has the advantages of environmental protection and resource recycling.

● Ensure that the recycling and treatment process of used batteries strictly abides by relevant laws and regulations to prevent secondary pollution. For example, wastewater, waste gas and waste residues in the recycling process must be effectively treated to reduce the impact on the environment.

● During the recycling process, attention should be paid to the safety performance of the battery to ensure that no safety accidents will occur during its use.

The recycling of lithium iron phosphate batteries involves multiple links and technical means. With the continuous advancement of technology and the support of relevant policies and regulations, the recycling of lithium iron phosphate batteries will develop in a more efficient, environmentally friendly and economic direction, thereby achieving sustainable use of resources and promoting environmental protection.