Blog

Hot Category

Latest Blog

18 Jan 2025

Nlelsen

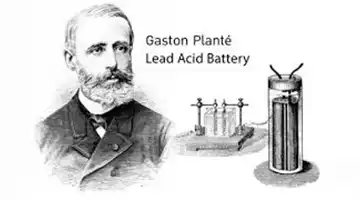

The development history of lead-acid batteries is like a technological epic full of innovation and breakthroughs. Since it was invented by Plant in 1859, it has gone through more than a century.

In the early 19th century, lead-acid batteries took the lead in the field of chemical power sources with its many advantages. Its low price and the convenience of obtaining raw materials allowed it to quickly emerge in many fields. At the same time, its performance in reliability is also quite outstanding. Whether it is high-current discharge or in a wide range of ambient temperatures, it can work stably.

Entering the 20th century, lead-acid batteries ushered in many key improvements. From the perspective of performance improvement, the performance of energy density, cycle life and high-rate discharge has been significantly improved. However, open-type lead-acid batteries expose two more serious problems. On the one hand, at the end of charging, water will be decomposed to produce hydrogen and oxygen, which requires frequent acid and water addition operations, greatly increasing the complexity of maintenance; on the other hand, when the gas overflows, it will be mixed with acid mist, which will not only corrode the surrounding equipment, but also pollute the environment, seriously limiting its application in many scenarios.

In order to overcome these problems, countries around the world have actively invested in the research and development of sealed lead-acid batteries. In this research and development process, there have been many exploratory attempts. For example, a patent published by Thomas Edison in 1912 proposed the use of platinum wire in the upper space of the single cell, relying on the heat of the platinum wire when the current passes through to become a catalyst for the combination of hydrogen and oxygen, trying to make the precipitated hydrogen and oxygen recombine and return to the electrolyte. However, this idea has not been put into practical application. There are three main problems: First, the platinum catalyst will soon fail and cannot continue to work; second, the stoichiometric number of gas precipitation is not based on the hydrogen-oxygen ratio of 2:1, and gas will still be generated inside the battery; third, this device is at risk of explosion.

In the 1960s, the American Gates Company invented lead-calcium alloy, which greatly promoted the development of sealed lead-acid batteries. Major battery companies in the world invested a lot of manpower and material resources to carry out further research and development. During the implementation of the US moon landing plan in 1969, sealed valve-regulated lead-acid batteries and cadmium-nickel batteries were both included in the candidate list of power sources for lunar rovers. Although cadmium-nickel batteries were eventually adopted, this event undoubtedly gave the sealed lead-acid battery technology an opportunity for further development. From 1969 to 1970, the American EC Company manufactured about 350,000 small sealed lead-acid batteries. This battery uses glass fiber cotton separators and belongs to the lean liquid system. It can be said to be the earliest commercial valve-regulated lead-acid battery, but people at that time had not yet recognized its oxygen recombination principle. In 1975, after years of hard work and high investment, GatesRutter Company obtained an invention patent for a D-type sealed lead-acid dry battery, which became the prototype of today's valve-regulated lead-acid battery (VRLA).

With the development of the industrial revolution, the continuous growth of demand for electricity has become a powerful driving force for the continuous advancement of lead-acid battery technology. In the early 20th century, Thomson invented a more effective lead-acid battery design and successfully applied it to the automobile starting system, thus establishing the important position of lead-acid batteries in automobile power systems. After that, its application scope gradually expanded to communications, railway transportation and other fields. During the industrial development stage from 1930 to 1980, large lead-acid battery manufacturers were established all over the world, and automated production lines gradually replaced the manual production mode. During this period, progress was made in the improvement of the addition method of positive active materials and the use of electrolyte additives, and the battery performance and life were significantly improved. In the 1980s, with the rise of electronic devices, the demand for small lead-acid batteries increased sharply, and the scope of application also extended from automobile starting systems to many fields such as portable electronic products.

In the technological innovation stage since the 1990s, advanced lead-acid battery technology has flourished since the 21st century. Researchers continue to explore and innovate in response to the limitations of traditional lead-acid batteries. In terms of positive electrode materials, traditional lead dioxide positive electrode materials have been replaced by more excellent active materials. The application of antimony trioxide (Sb₂O₃) and graphene has significantly improved the battery energy density and cycle life; the improvement of electrolyte technology has enabled the new formula to reduce internal impedance, which has improved battery efficiency, charging and discharging speed, and enhanced battery safety; the optimization of structural design has adopted advanced manufacturing processes and design concepts such as spraying technology and 3D printing to produce a lighter and higher-performance battery structure.

Today, lead-acid batteries have been widely used in many economic fields such as transportation, communications, electricity, military, navigation and aviation, and have generated a huge market scale worldwide. The global advanced lead-acid battery market size in 2023 is about several billion US dollars, and it is expected to reach a growth rate of tens of billions of US dollars by 2030. As the world's largest producer and consumer of lead-acid batteries, China's market size accounts for a considerable proportion of the global market. With the rapid development of the new energy vehicle industry and the continuous breakthroughs in energy storage technology, China's advanced lead-acid battery market has shown a strong growth momentum and is expected to reach a considerable scale by 2030.

Despite the progress made in the development of lead-acid batteries, they still face some challenges, such as pollution problems, adverse effects on the environment, and relatively high maintenance requirements. However, as researchers continue to explore new environmentally friendly battery technologies, lead-acid batteries continue to evolve and continue to play their role in various fields.